You’re only 30 to 40 percent done when your hardware design is functionally successful (i.e., your prototype works). Shipping a real product involves multiple interdependent steps across engineering, supply chain, compliance, and operations. Here’s a detailed breakdown from functional design to selling on eCommerce platforms:

Table of Content

Toggle1. Design Verification

Even if your prototype works, you need to prove it works reliably and repeatedly.

What this involves:

- Functional Testing: Confirm all features work across temperature, voltage, and mechanical tolerances.

- Regression Testing: Ensure fixes or improvements don’t break existing features.

- Field Testing: Run real-world usage tests for durability, wireless performance, UX, etc.

- Fail Mode Analysis: Push the device to limits to understand how it fails and how gracefully.

Goal: Confidence that the design performs in all expected scenarios.

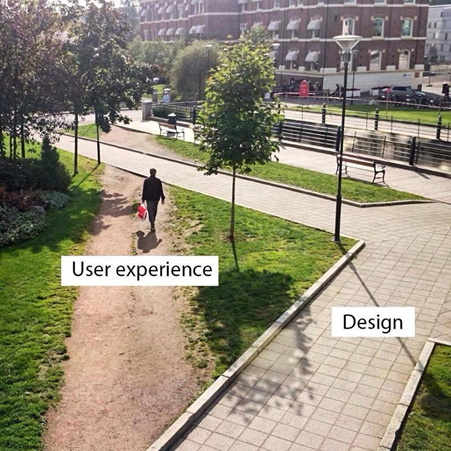

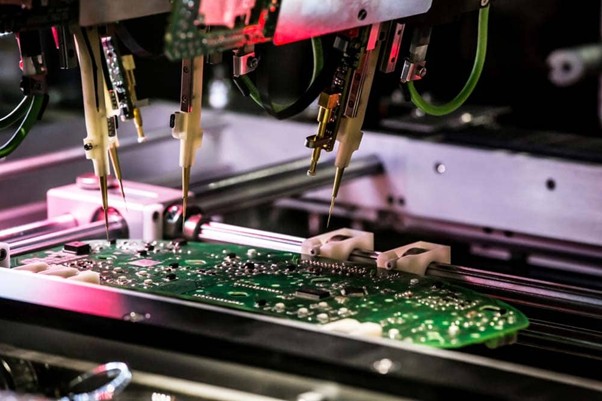

2. Design for Manufacturing (DFM)

Your prototype may be partially hand-assembled. Mass production needs a different mindset.

DFM covers:

- Component substitution: Replace exotic or hard-to-source parts with standard ones.

- Layout adjustments: Optimize PCB for pick-and-place machines, penalization, test pads.

- Mechanical design tweaks: Ensure moldability, standard fasteners, tolerance stacks.

- Assembly simplification: Fewer steps, snap fits, fewer screws.

Goal: A design that factories can build quickly, cheaply, and repeatedly.

Image Source: SixSigma.us

3. Design for Testing (DFT)

Testing one unit manually is fine. Testing thousands is not.

DFT activities:

- Add test points to PCBs for automated jig testing.

- Include self-test firmware to run basic functional checks at the factory.

- Design fixtures and jigs that allow production line operators to test key functions fast.

- Plan for end-of-line testing, including flashing firmware and checking BLE/Wi-Fi connectivity.

Goal: High coverage testing at speed without requiring engineering presence.

4. Certifications and Compliance

You can’t legally sell the product without passing regulatory compliance.

What you’ll likely need:

- EMC/EMI testing (e.g., CE, FCC): Tests for radiated emissions and immunity.

- Safety tests (e.g., IEC 62368): Ensures device is safe under fault conditions.

- Battery transport certification (e.g., UN38.3): For lithium batteries.

- RoHS/REACH compliance: Material-level safety declarations.

For connected products (BLE, Wi-Fi, etc.), compliance with the EU’s RED Cybersecurity Delegated Act is required from August 1, 2025. This includes protection of user data, secure communication, and resilience against misuse. Failing to meet this may block product entry into the EU market.

Process:

- Work with a certified lab (e.g., TÜV, Intertek).

- Prepare technical documentation, test samples.

- Budget 4–8 weeks and €5,000–€30,000 depending on region and category.

Goal: Legal approval to sell in your target regions.

5. Pilot Manufacturing Run

Before scaling, run a small batch (50–500 units).

Why:

- Catch issues in assembly, testing, packaging.

- Verify firmware flashing, configuration steps.

- Validate labeling, barcoding, packaging.

Things to check:

- Yields: % of units passing tests.

- Time per unit.

- Factory documentation, SOPs.

Goal: Verify that the product can be manufactured at scale without major defects.

6. Packaging and Labeling

Product needs to survive shipping (and attract buyers if it’s B2C).

Packaging steps:

- Structural design: Inner trays, ESD protection, outer box.

- Artwork design: Regulatory labels, QR codes, barcodes, user-facing branding.

- Unboxing experience: Especially important for consumer devices.

- Drop testing: To ensure packaging protects the product during transport.

Goal: A package that’s compliant, protective, and ready for eCommerce, B2B or B2C deliveries.

Image Source: ZenPack

7. Logistics and Fulfillment

Now you need to store and move your product

Options:

If it’s a large-scale eCommerce or consumer electronics product.

- Use a 3PL (third-party logistics provider) for warehousing and shipping.

- Ship direct-to-customer from your own facility (not scalable).

- Use Fulfilled by Amazon (FBA) or similar.

For B2B deliveries, 3PL may still be useful.

Considerations:

- Import/export documents (customs, duties, etc.).

- Warehousing, SKU management, returns processing.

- Tracking and order management integration.

Goal: Smooth, predictable delivery to customers.

8. eCommerce Setup (if B2C)

You now need to be discoverable and sell online.

Steps:

- Create product listings on Amazon, Shopify, or similar.

- Provide clear specs, certifications, support info.

- Capture product images and demo videos.

- Set up customer support (email, returns, warranty).

- Manage inventory integration with your logistics provider.

Compliance:

- Amazon may ask for certification documents before listing.

- You may need product liability insurance.

Goal: A live product page that builds trust and converts visitors.

9. Post-Sale Support

This often makes or breaks the long-term success of hardware.

Includes:

- Firmware updates (via app, OTA if supported).

- RMA handling for returns.

- Customer queries and documentation.

- Monitoring reviews and feedback loops for V2.

Summary Path:

In the following order

- Functional prototype

- Design verification

- DFM/DFT

- Certifications

- Pilot run

- Packaging

- Logistics

- eCommerce listing

- Post-sale support

If you need help with design and development of electronics, embedded and IoT hardware that qualifies for certifications, actually ships and is profitable, contact us for a free initial consultancy.