Wearable devices often use Lithium-Ion or Lithium Polymer batteries, which have a high flammability risk. This is due to higher energy density and the use of flammable electrolytes inside Lithium-based batteries.

Safety against fire and explosion is critical in wearable and consumer electronic devices (this goes without saying). But how do the designers ensure highest level of battery safety in such devices?

Table of Content

ToggleProtections Needed for Lithium Batteries

When designing systems with Lithium batteries, several safety factors must be considered. We will explore the necessary protections in detail below. This discussion assumes the use of single-cell lithium batteries, as they are the most commonly used in wearable devices.

- Deep Discharge Protection

Deep Discharge occurs when the battery voltage is allowed to go under its safe lower cutoff voltage (For LiFePO4 a deep discharge voltage would be <2.65 V). This should be protected against even when the battery is not being used. Voltage dropping below the lower cutoff voltage will lead to a reduction in the amount of charge it can hold.

- Load Regulation

Load Regulation refers to the control and management of the current and voltage supplied to the battery during charging and discharging. This feature ensures that the battery is charged and discharged with the following features implemented:

-

- Current Regulation

Current regulation ensures that you do not draw more current than the battery can provide safely. Safe battery charge and discharge currents are defined by the C rating (discharge and charge) of the battery.

-

- Overvoltage Protection

You need to protect your battery from any voltage higher than it is designed to handle. E.g. applying 5V to a 4.2V Lithium cell will damage your battery permanently and is a fire hazard.

-

- Undervoltage Lockout

This protection prevents the battery voltage from dropping below its minimum allowable voltage during normal operation (For LiFePO4 it is 2.65V). Dropping below this setpoint can cause problems with the circuitry on your Printed Circuit Board (PCB) and damage the battery.

-

- Cell Temperature Regulation

The manufacturer will specify safe discharge and charge temperatures for your battery. The battery should stay inside this temperature range for safe operation. Temperature regulation should limit charge/discharge currents when an over–temperature (hot) or under-temperature (cold) event is detected. You can easily monitor your battery temperatures using 1 or more NTC thermistors.

- Short-Circuit Protection

Current drawn by a short circuit can be large and can lead to several problems such as loss of battery capacity, swelling, or worse, PCB traces getting burnt, battery wires and connectors melting and catching fire.

- Reverse-Polarity Protection

Improper battery connection can lead to short circuit conditions. Add a circuit on your PCB to provide reverse polarity protection.

- Water Resistance / Splash Resistance (if the application requires it)

Ensuring that the enclosure is water-tight removes the risk of your battery getting exposed to water. Water can directly short out the terminals of a Lithium battery!

- Battery Size Fitting the Enclosure + Some Room

Ensure that battery size is compatible with your enclosure.

Leave space in your enclosure for battery to swell. As batteries age, they may swell up due to gas build up inside the pack.

Electrical Recommendations for Safety

1. Select a Certified Battery with an NTC Thermistor and preferably with a PCM

Ensure the battery you have selected has been certified. Certifications can cover various safety aspects of batteries. IEC 62133-2 sets the safety requirements for portable cells for use in portable applications. UL 1642 and UL 2054 specify the requirements needed for consumer electronics.

Lithium-Ion batteries sold in the EU must comply with RoHS and bear the CE marking. The CE symbol indicates that all applicable CE marking-related regulations have been complied with. Meanwhile, ROHS is the Restriction of Hazardous Substances Directive.

CE and ROHS indicate compliance with certain regulations, they do not necessarily imply that the battery is of high quality. For safety critical applications, select a UL 1642 or an IEC 62133 certified battery. This standard curtails rigorous testing procedures. The following are some of the tests performed when UL 1642 certification is applied to a battery model:

-

- Short-Circuit Test

- Abnormal Charging Test

- Heating Test

- Temperature Cycling Test

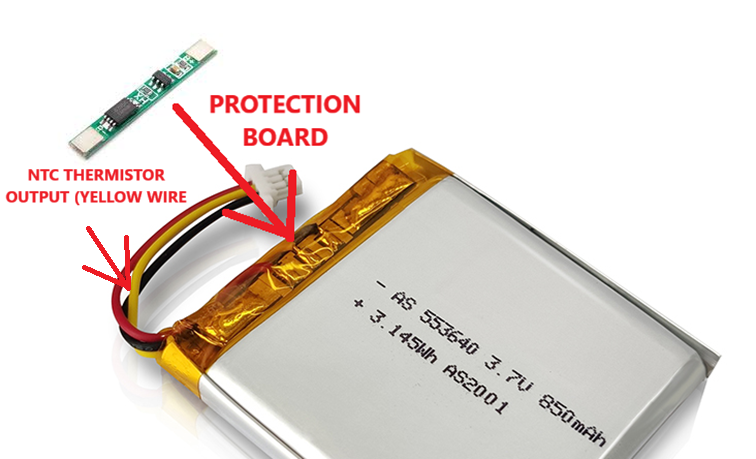

LiPo batteries often have a small Protection Circuit Module (PCM) board with a NTC Thermistor (Negative Temperature Coefficient) connected directly to the battery itself. An example of this PCM and NTC is shown below (Fig8).

Figure 8: An example of a battery with a basic protection board and NTC thermistor built in

It is recommended to use a battery with both protections built in. PCM boards are the first level of protection in your system. The NTC thermistor is an analog sensor that you can use to read battery temperatures from. This feature will not be useful unless your charge controller / BMS / microcontroller reads it. An NTC thermistor will give you an analog voltage that will directly correlate to the temperature of your battery. Nevertheless, your PCB should have all protections built into it regardless of a PCM (Protection Circuit Module) or an NTC thermistor on the battery. You may have multiple NTC thermistors to monitor different regions of your battery or your PCB itself.

Treat the PCM as a backup to your safety features implemented on the main board because PCM protections can vary on different battery models. Typical protections offered are overcharge protection, over-discharge protection, overcurrent and short circuit protections and protections to cut-off battery beyond recommended cell temperatures.

Don’t assume all the above protections as default in every battery PCM. Ask the manufacturer.

Only purchase certified batteries from reputable vendors as substandard batteries are prevalent in the market.

2. Add and Configure a Battery Management IC on Your Main Board

Monitoring a battery depends mainly on battery volts, current and chemistry. Wearable electronic devices often use single-cell Lithium batteries (3.7V nominal) with varying currents (typically less than 2000mA).

Battery charger chips and Battery Management System (BMS) chips are two different things. A BMS chip can measure state of charge, current, balance multiple cells, manage overvoltage etc. Some BMS chips can also communicate and send this data to a microcontroller. On the other hand, a lot of Battery charger chips will usually only manage charging and discharging your battery.

There is a huge variety of BMS and battery chargers available from various IC manufacturers. Select an IC that has all the necessary features to satisfy the electrical conditions related to battery safety and that meets your functional requirements. You can also add a battery management system (BMS) alongside a Battery Charge Management Controller which has all the protections defined earlier. The decision to use one or both depends on the complexity of the battery setup and if you need to read any specific information about the battery.

The electrical protections needed can be achieved using an integrated charger IC like the . To achieve the remaining protections, you may need additional components. Another example is the MCP73833 which has fewer features than the MCP73871. Again, you need to evaluate each chip to understand what it offers and what is missing for your particular use case!

A good example of a single cell BMS chip is the MAX17260. This BMS chip is an effective device for measuring important information about the battery like state of charge, state of health, time to empty, time to full charge. This chip can also communicate over I2C to convey this information to your main microcontroller. In a wearable device, this information is quite useful.

- Select & Configure BMS IC according to the Chemistry of the Battery

There are a lot of different battery technologies! The Lithium-Ion terminology applies to more than 6 different types of Lithium-Ion chemistries like Lithium Cobalt, Lithium Phosphate etc.

While designing your circuit, ensure that the chips you select will work with the specific battery chemistry you use. Each type of battery has its own specific conditions that your system must cater to.

Let us compare the EOC (End of charge) voltages of LiCoO2 (typically called as “Li-Ion”) and LFP (LiFePO4).

LiCoO2 EOC Voltage: 4.2 Volts

LiFePO4 EOC Voltage: 3.65 Volts

Clearly, this voltage difference requires different thresholds for these two battery types. Your system must be designed for the corresponding chemistry.

A simple way to identify battery chemistries is to look at the nominal voltages. These can help you identify the chemistry of the battery. LFP (LiFePO4) will usually have a nominal voltage of 3.2 Volts while LiCoO2 has a nominal voltage of 3.7 Volts (nominal voltage is not charge or discharge cutoff voltage).

Example of how to configure a chip according to your battery:

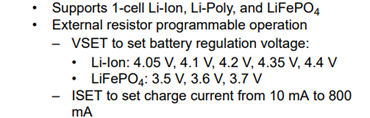

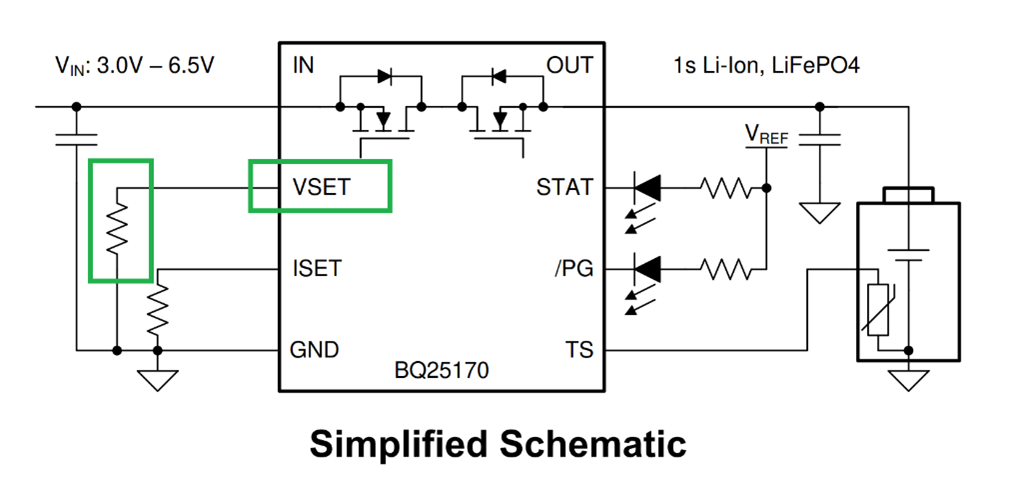

The BQ25170 from Texas Instruments is designed to be used with either Lithium-Ion or LiFePO4 chemistries. It can be configured for either one through an external resistor to control the charging voltage. (Fig. 1 and Fig. 2)

Fig. 1 BQ25170 external resistor setting

(Image Source: Texas Instruments BQ25170 Datasheet)

Fig. 2 BQ25170 external resistor setting

(Image Source: Texas Instruments)

- Inefficient Charging can heat up your system unnecessarily. Plan accordingly!

Charging your Li-Ion battery without overheating your PCB is important.

Before moving forward, two categories of chargers you should know about: linear chargers and switch-mode chargers.

Linear charge controllers are cheap and simple to add in your design. Switch mode controllers are typically more expensive and require more surrounding components.

To reduce heating up of the system during charging, we recommend using a switch mode charge controller.

These controllers have a high (>90%) power conversion efficiency and generate less heat.

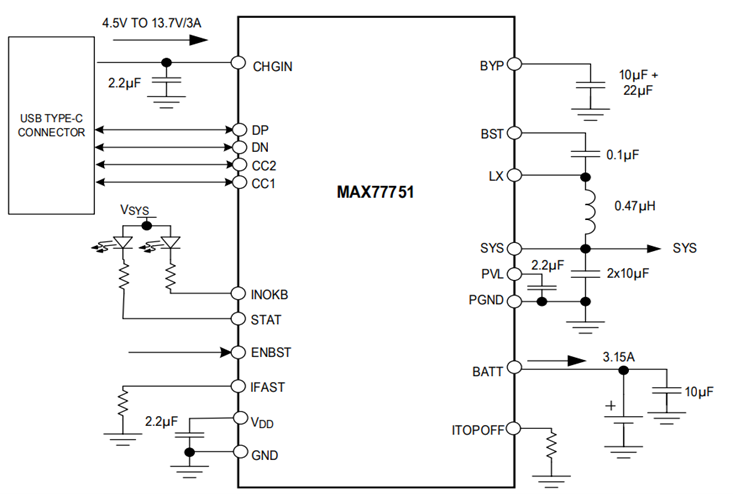

Fig. 3 MAX77751 is a switch mode charge controller for Lithium batteries

(Image Source: Microchip Technology Inc.)

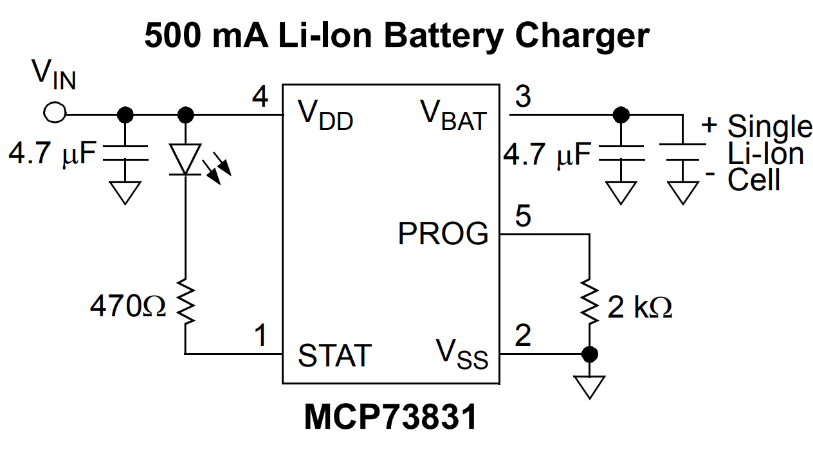

As a rule of thumb, for charge/discharge currents less than 500mA and a small voltage difference between your input voltage and battery voltage, you can consider a linear charge management controller for its simplicity and low cost (Fig. 4). For higher currents and more difference of volts, calculate estimated temperature rise based on the thermal resistance and junction temperature information provided in the datasheet.

Fig. 4 MCP73831 is a linear charge controller for Lithium batteries

(Image Source: Microchip Technology Inc.)

3. Ensure Reliable Electrical Connection Between the Battery and PCB (Main Board)

Maintain a reliable electrical connection between your battery and your PCB. Bad connections can lead to the overheating of connection due to increased resistance of the poor electrical connection.

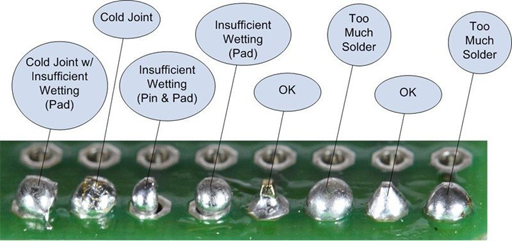

- Soldering Battery Cables Directly on the PCB

Battery cables may also be soldered directly to the PCB. Correct soldering is important for a reliable electrical connection. A visualization of good vs bad soldering is shown below:

Fig. 5 Different types of soldering conditions can be observed

(Image Source: PCBGOGO)

- Using Battery Connectors

UL940-V0 compliance is a good guideline for selecting battery connectors. This standard recommends, among other things, that the plastic of the connectors is flame retardant.

Use connectors that are rated for the appropriate battery currents. Battery connectors and wiring must be set to withstand >=150% of your average current. The appropriate wire gauges will be decided by your actual peak and steady state currents. Remember, the current rating of a wire is defined by how much the copper in your wire heats up. A wire placed in the air will have a higher current rating than one placed inside a sealed plastic box. If in doubt, choose a thicker wire to be safe.

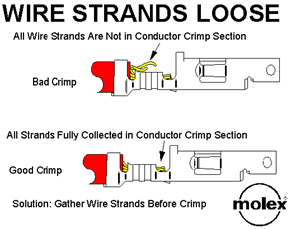

If using connectors, ensure that your crimping is done professionally. Each type of crimp can have its own methodology. Bad crimping can create poor electrical connectivity.

An example of bad crimping is shown below (Fig. 6)

Figure 6: The difference between a poorly crimped and well crimped connector

(Image source: Molex)

4. Test Your System Thoroughly

After designing the hardware, extensively test your system with the battery installed to test the safety features implemented. This ensures that the design of the system is foolproof and allows you to check for any manufacturing defects on the PCB or elsewhere.

Below are some example tests to verify your battery safety features:

-

- Thermal Stress (Over and Under)

- Thermal Cycling

- Simulated Thermal Runaway

- Drops and throws

- Vibration tests

- Reverse Polarity tests

- Insulation testing

- Overcurrent Testing

- Short-circuit Testing

- End-of-Life Testing (Accelerate the battery charge and discharge cycles)

The test results will help you identify design flaws and improve your system before the product is released to the customers.

Mechanical Recommendations for Safety

1. Plan Your Battery Placement Carefully

Clearance must be given between the following items in the system:

Battery to enclosure, Battery to battery (multiple cell systems), Battery to PCB.

The mechanical enclosure for your device should provide clearance for batteries to bloat. Bloating (or swelling) usually is most visible on the largest plane of the battery. It can happen due to battery aging, over temperature, deep discharge, and manufacturing defects. (Fig. 7)

Figure 7: An example of a battery swelling inside an enclosure

(Image source: bebat)

Bloating can lead to the battery pouch getting punctured. The resulting gas released is toxic and flammable!

Be sure to provide electrical insulation around any exposed electrical contacts close to the battery. This insulation should have sufficient dielectric strength. These electric contacts can short out via the aluminum body of a pouch-style battery.

Large enclosures can be designed to have a pressure relief valve (if IP-XY is needed (water and dust resistance)). If IP-XY compliance is not needed, the enclosure should have special directed vents in the mechanical design to vent hot gases away from the user. The enclosure must be sturdy enough and its build quality must be suitable enough to withhold a battery fire. The material for the enclosure must be UL94-V0 compliant (flame retardant).

2. Position Your Battery Away from Heat and Sharp Objects

The mechanical placement of the battery must ensure that no PCB components can puncture it. Puncturing a Lithium-Ion battery results in the electrolyte getting exposed to air. This electrolyte can ignite on exposure to air.

Battery placement should also be far away from any high temperature areas on the PCB (if possible) as this can create thermal runaway situations. Thermal runaway is a self-reinforcing cycle that can start from overheating a battery. As the temperature increases, chemical reactions can produce flammable gas and heat which causes the battery to swell up like a balloon. If the battery is punctured, this gas can catch fire. The additional heat causes more gas to be released and that elevates the problem even further.

3. Heat Dissipating Design

Design your wearable device to dissipate heat efficiently by incorporating metal frames or layers of heat-dissipating materials like aluminum or copper (beware of shorts!). That will prevent battery overheating. If your enclosure is metallic, consider adding a thermal pad between your PCB and your enclosure to enhance thermal conductivity. The thermal pad will essentially cause your enclosure to turn into a large heatsink!

A good way to prevent PCB damage is for your microcontroller to continuously monitor battery and PCB temperatures using NTC thermistors. In case the PCB is heating up unnecessarily, or the ambient temperature is too high, your microcontroller can shut down any peripherals that it can.

Summary:

Ensure your wearable electronic device incorporates critical battery safety measures. Implement protections like deep discharge prevention, current regulation, overvoltage protection, and undervoltage lockout to maintain battery health. Integrate short-circuit protection and design for effective thermal management during charging and discharging to prevent overheating and potential hazards. Be sure to accommodate battery swelling in your enclosure design, and always use certified batteries with built-in protection circuits for added safety. Integrate a battery management system (BMS) in your design to monitor battery health and performance.